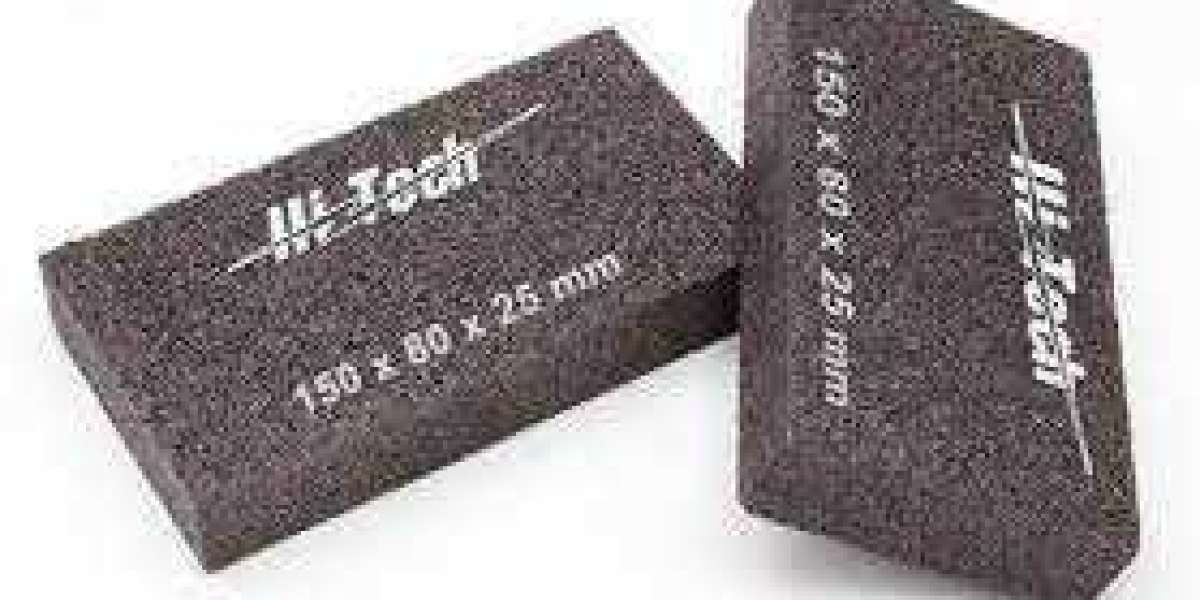

In the world of metalworking, achieving precise surface finishes is crucial for countless components. Grinding wheels are a mainstay for this task, but for some jobs, there's a hero that often goes unrecognized: grinding segments.

Grinding segments are essentially mini grinding wheels attached to a metal plate. They come in various shapes and sizes, each suited for specific grinding applications. They're most commonly used on rotary table surface grinding machines.

Here's what makes grinding segments stand out:

- Heavy-duty stock removal: Their design allows for aggressive grinding, making them ideal for quickly removing large amounts of material. The open spaces between the segments help to prevent clogging and overheating.

- Cool grinding: The air gaps between the segments promote better heat dissipation, reducing the risk of warping or burning the workpiece.

- Versatility: Segments come in a wide range of abrasive grits and bond types, allowing you to tackle various materials and achieve different surface finishes.

- Cost-effective: Since segments are replaceable, you only need to replace the worn-out portion, making them a more economical option in the long run.

So, next time you're working on a surface grinding project, consider the power of grinding segments. They might just become your go-to tool for achieving flat, precise surfaces efficiently.