Underground Warning Mesh Exporters in Ahmedabad is a critical component in the protection and maintenance of subsurface utilities. These meshes serve as a visual alert to prevent accidental damage during excavation activities, safeguarding vital infrastructure such as gas pipelines, electrical cables, water lines, and telecommunications networks. As urban development and infrastructure projects expand, the need for effective warning systems becomes increasingly important. This article delves into the purpose, benefits, types, and installation practices of underground warning mesh, providing a comprehensive guide for contractors, engineers, and property owners.

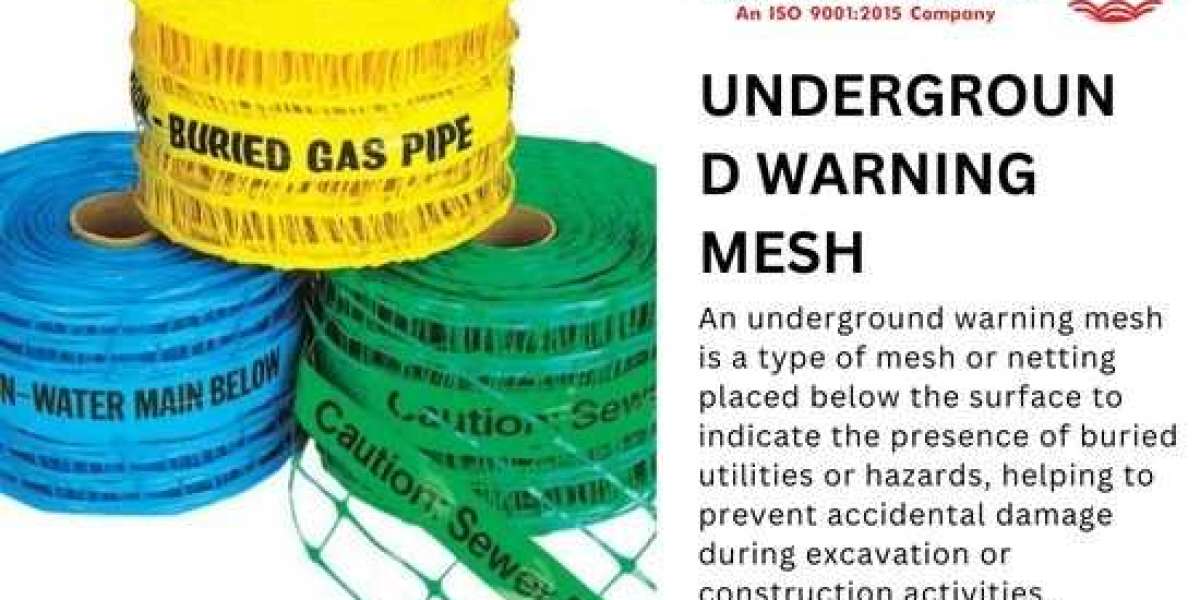

What is Underground Warning Mesh?

Underground warning mesh is a brightly colored, durable plastic mesh that is buried a short distance above subsurface utilities. Its primary function is to act as a visible alert during digging activities, signaling to workers that they are approaching a potentially hazardous utility. The mesh is usually made from high-density polyethylene (HDPE) or other resilient materials that can withstand soil pressure and environmental conditions.

Importance of Underground Warning Mesh

Preventing Damage to Utilities: Accidental damage to underground utilities can result in severe consequences, including service interruptions, costly repairs, and safety hazards. By providing a clear visual warning, Warning Mesh Manufacturers in India helps prevent such incidents, ensuring that utilities remain intact and operational.

Enhancing Safety: Safety is a paramount concern during any excavation project. Striking an underground gas pipeline or electrical cable can lead to explosions, electrocution, or other life-threatening situations. Warning mesh significantly reduces these risks by alerting workers before they reach the utility.

Compliance with Regulations: Many regions have stringent regulations regarding the marking and protection of underground utilities. Installing warning mesh can help ensure compliance with these laws, avoiding potential fines and legal issues.

Types of Underground Warning Mesh

There are several types of Warning Mat Manufacturers in Ahmedabad available, each designed for specific applications:

Detectable Warning Mesh: This type of mesh includes embedded metallic wires or strips, making it detectable by metal detectors. Detectable warning mesh is particularly useful for utilities that may not be easily visible during excavation, such as fiber optic cables or plastic pipes.

Non-Detectable Warning Mesh: Non-detectable warning mesh is made entirely of plastic and does not include any metallic components. It relies solely on its bright color to serve as a warning signal. This type of mesh is commonly used for utilities that are already easily locatable or when electronic detection is not required.

Custom Printed Warning Mesh: Custom printed warning mesh can be tailored to include specific warnings or information relevant to the utility it protects. For example, it may include the type of utility (e.g., "Gas Line Below"), company logos, or contact information for emergency situations.

Installation Practices

Proper installation of underground warning mesh is crucial to its effectiveness. Here are the key steps involved:

Pre-Installation Planning: Before installation, it is essential to conduct a thorough site survey to identify the location and depth of existing utilities. This helps in planning the optimal placement of the warning mesh.

Placement of the Mesh: The warning mesh should be placed a certain distance above the utility it is protecting. The typical depth ranges from 300mm to 600mm, depending on the type of utility and the surrounding soil conditions. The mesh should be wide enough to cover the entire area above the utility, providing a comprehensive warning barrier.

Securing the Mesh: To ensure that the mesh remains in place, it should be secured with stakes or pins at regular intervals. This prevents the mesh from shifting or being displaced by soil movement.

Backfilling: Once the mesh is in place, the trench should be backfilled carefully to avoid disturbing the mesh. Proper compaction of the soil is also necessary to maintain the integrity of the warning system.

Benefits of Using Underground Warning Mesh

Cost Savings: By preventing accidental damage to utilities, warning mesh can save significant costs associated with repairs and downtime. It also reduces the likelihood of costly legal disputes resulting from service interruptions or accidents.

Environmental Protection: Preventing damage to utilities, particularly those carrying hazardous substances, also protects the environment. Leaks or ruptures in pipelines can result in soil and water contamination, which can have long-term ecological impacts.

Improved Project Efficiency: Having a clear visual warning system in place allows excavation projects to proceed more smoothly and quickly. Workers can excavate with confidence, knowing they have an early warning system to prevent accidental strikes.

Versatility: Underground warning mesh is versatile and can be used in a wide range of applications, from residential and commercial developments to large-scale infrastructure projects.

Conclusion

Underground warning mesh is an indispensable tool for the protection of subsurface utilities. By providing a clear and effective visual warning system, it helps prevent accidental damage, enhances safety, and ensures compliance with regulations. Whether for residential, commercial, or large-scale infrastructure projects, the use of underground warning mesh is a prudent investment that offers significant benefits in terms of cost savings, environmental protection, and project efficiency. As the demand for secure and reliable utility networks continues to grow, the importance of effective warning systems like underground warning mesh cannot be overstated.

Frequently Asked Questions (FAQs)

What is the primary purpose of underground warning mesh?

The primary purpose of underground warning mesh is to provide a visual alert during excavation activities, signaling the presence of underground utilities and preventing accidental damage.

How deep should underground warning mesh be buried?

The depth at which underground warning mesh should be buried typically ranges from 300mm to 600mm above the utility it is protecting. The exact depth depends on the type of utility and soil conditions.

Can underground warning mesh be customized?

Yes, underground warning mesh can be customized with specific warnings, company logos, and contact information. Custom printed warning mesh provides tailored alerts relevant to the utility it protects.

What materials are used to make underground warning mesh?

Underground warning mesh is usually made from high-density polyethylene (HDPE) or other durable plastic materials that can withstand soil pressure and environmental conditions.

What is the difference between detectable and non-detectable warning mesh?

Detectable warning mesh includes metallic wires or strips, making it detectable by metal detectors, while a non-detectable warning mesh is made entirely of plastic and relies on its bright color for visibility.